In today's fast-paced industrial landscape, the demand for high-quality plastic parts is ever-increasing. Key players in this sector, plastic parts manufacturers, are pivotal in producing components that meet stringent quality and precision standards. This article delves into the crucial aspects of plastic parts manufacturing, mould processing, and CNC processing products, highlighting their significance and applications across various industries.

Understanding the Role of a Plastic Parts Manufacturer

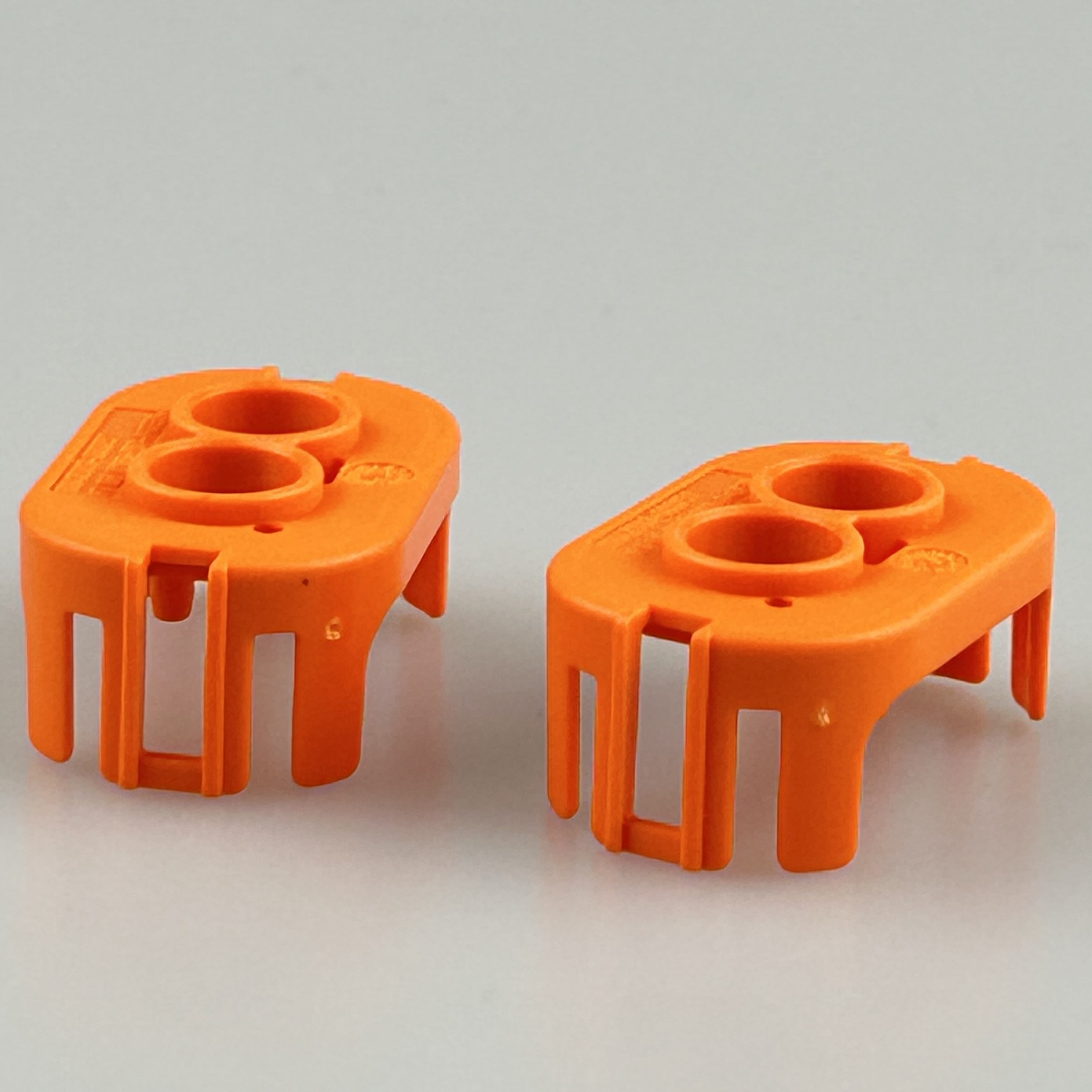

A plastic parts manufacturer specializes in producing plastic components used in diverse applications, ranging from automotive and aerospace to electronics and consumer goods. These manufacturers leverage advanced technologies and processes to ensure their products meet the highest quality standards.

Key Responsibilities:

Design and Development: Manufacturers work closely with clients to design and develop custom plastic parts that meet specific requirements.

Material Selection: Choosing the right plastic material is crucial for ensuring the durability and functionality of the final product.

Quality Control: Rigorous quality control measures are implemented to ensure each part meets the required specifications.

The Importance of Mould Processing

Mould processing is a critical step in plastic parts manufacturing. It involves creating molds that are used to shape the plastic into the desired forms. The quality of the mold directly impacts the accuracy and finish of the final product.

Steps in Mould Processing:

Design and Prototyping: Creating detailed designs and prototypes to ensure the mold will produce the desired part accurately.

Material Selection: Choosing the right material for the mold to ensure it can withstand repeated use and maintain precision.

Machining and Finishing: Using advanced machining techniques to create the mold, followed by finishing processes to achieve the required surface quality.

The Role of CNC Processing in Plastic Parts Manufacturing

CNC (Computer Numerical Control) processing plays a vital role in the production of high-precision plastic parts. CNC machines are used to perform various operations such as cutting, drilling, and milling with high accuracy.

Benefits of CNC Processing:

Precision and Accuracy: CNC machines can produce complex shapes with tight tolerances, ensuring each part meets the exact specifications.

Efficiency: CNC processing is highly efficient, allowing for the production of large quantities of parts in a relatively short time.

Versatility: CNC machines can work with a wide range of materials and are suitable for producing parts of various sizes and complexities.

Applications Across Industries

Plastic parts manufactured through advanced mould processing and CNC processing are used in various industries due to their reliability and precision. Some notable applications include:

Automotive Industry: Engine components, interior trims, and exterior body parts.

Aerospace Industry: Lightweight, durable components for aircraft.

Electronics: Housings and internal components for gadgets and appliances.

Medical Devices: Precision parts for diagnostic equipment and surgical instruments.

Conclusion

The role of plastic parts manufacturers is indispensable in today's industrial landscape. Through advanced mould processing and CNC processing, these manufacturers produce high-quality, precision parts that meet the demanding requirements of various industries. By leveraging cutting-edge technology and adhering to strict quality control measures, plastic parts manufacturers ensure their products stand up to the challenges of modern applications.