In the realm of manufacturing, plastic injection molding stands out as a versatile and efficient process for creating a wide array of products. From intricate components to everyday items, plastic injection molding plays a pivotal role in various industries, including automotive, electronics, consumer goods, and medical devices.

What sets plastic injection molding apart is its ability to produce high-quality, precise, and complex parts with consistency and efficiency. This process involves injecting molten plastic material into a mold cavity under high pressure, where it cools and solidifies to form the desired shape.

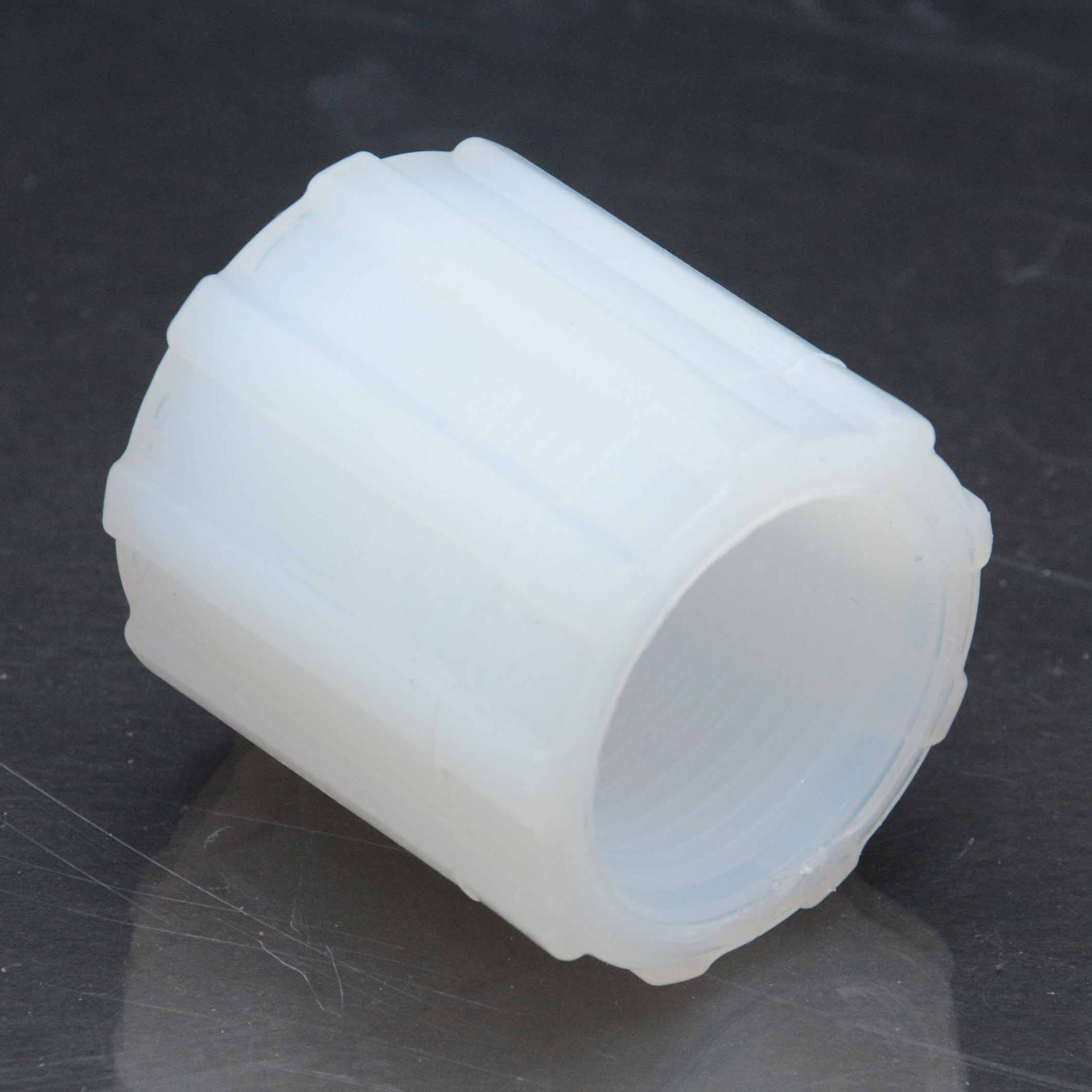

One of the key advantages of plastic injection molding is its versatility. Manufacturers can use a diverse range of thermoplastics and thermosetting polymers, allowing for the production of products with varying properties, such as strength, flexibility, and heat resistance. Additionally, plastic injection molding enables the incorporation of features such as inserts, threads, and undercuts, further expanding the design possibilities.

The automotive industry extensively relies on plastic injection molding for manufacturing interior and exterior components, dashboard panels, door handles, and even engine parts. In electronics, this process is utilized for producing housings, connectors, and enclosures for devices like smartphones, laptops, and household appliances.

Consumer goods benefit greatly from plastic injection molding, with products ranging from kitchen utensils and toys to packaging containers and cosmetic accessories. Medical devices, including syringes, surgical instruments, and implantable components, also utilize this process due to its ability to meet stringent regulatory requirements and ensure product consistency and safety.

To achieve optimal results, manufacturers employ advanced technologies and precision equipment in the plastic injection molding process. Computer-aided design (CAD) software enables the creation of intricate mold designs, while computer numerical control (CNC) machining ensures the precise fabrication of molds to exact specifications.

Quality control measures are integral to the plastic injection molding process, with rigorous inspections conducted at every stage to verify dimensional accuracy, surface finish, and material properties. This meticulous attention to detail helps uphold the highest standards of quality and consistency in the final products.

In conclusion, plastic injection molding is a cornerstone of modern manufacturing, enabling the creation of high-quality, intricate, and cost-effective products across various industries. With its versatility, efficiency, and precision, plastic injection molding continues to drive innovation and shape the future of product development.